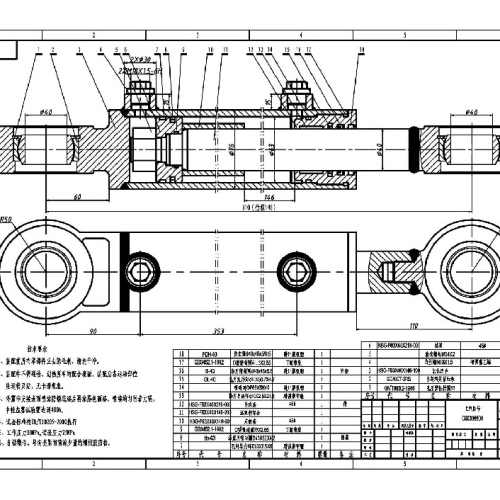

If you work with hydraulic systems, you’ve likely come across double-acting hydraulic cylinders. But do you really understand how they work? A double-acting hydraulic cylinder schematic provides a clear visual representation of its function, making it easier to troubleshoot, maintain, or even design a system.

What is a Double Acting Hydraulic Cylinder?

A double-acting hydraulic cylinder is a type of actuator that uses hydraulic pressure to move a piston in both directions—both extending and retracting. Unlike single-acting cylinders, which rely on an external force (like gravity or a spring) to return to position, double-acting cylinders provide force in both movements.

Key Components:

🛠️ Cylinder Barrel – The main housing that holds the piston and hydraulic fluid.

🛠️ Piston & Rod – Converts hydraulic pressure into mechanical force.

🛠️ Seals – Prevent leaks and maintain pressure.

🛠️ Ports – Two openings where hydraulic fluid enters and exits.

How a Double Acting Hydraulic Cylinder Operates

A double-acting cylinder has two hydraulic ports:

✅ Extension Stroke: High-pressure fluid enters the cap-end port, pushing the piston forward. The fluid in the rod-end chamber is forced out.

✅ Retraction Stroke: The process reverses—fluid enters the rod-end port, forcing the piston back, while the cap-end fluid exits.

A double-acting hydraulic cylinder schematic is a crucial tool for anyone working with hydraulic systems. Understanding how to read and interpret these diagrams can help with troubleshooting, maintenance, and even system design.

If you’re looking for high-quality double-acting hydraulic cylinders, feel free to contact us today for expert advice and premium products.

👉 [Call to Action: Explore Our Hydraulic Cylinder Collection or Get a Free Quote!]

It is recommended to use various types of hydraulic cylinders, double-acting hydraulic cylinders, and Power Steering Hydraulic Cylinders