If you’re in the dump truck business, especially with heavy-duty or high-capacity trucks, you’ve probably heard about 5 stage telescopic hydraulic cylinders. These aren’t just longer versions of the 4 stage cylinders—they offer a real advantage in height, stability, and compact design. In this article, we’ll walk through what a 5 stage telescopic hydraulic cylinder is, why it matters, and how to choose the right one for your truck setup.

What Is a 5 Stage Telescopic Hydraulic Cylinder?

A 5 stage telescopic hydraulic cylinder is a type of hydraulic actuator made up of five nested tubes (or stages) that extend sequentially. When hydraulic pressure is applied, each stage slides out in order, allowing a very long extension from a compact initial size. This makes it ideal for dump trucks that need to tilt their beds at a steep angle to fully unload cargo.

The main advantage here is reach. With five stages, you get more extension without increasing the retracted length. That’s key when space under the truck bed is limited, but you still need full dumping height.

Why Choose a 5 Stage Cylinder Over a 4 Stage?

Many operators ask: why not just stick with a 4 stage cylinder? The answer depends on the type of work your dump truck is doing. If you’re hauling loose gravel or light construction material, a 4 stage cylinder might do the job. But for heavier loads—wet soil, clay, or demolition waste—a 5 stage cylinder provides the extra lift needed to get the load out completely.

Another point is safety. More stages allow a smoother, more controlled extension. That reduces strain on the truck chassis and minimizes the risk of tipping, especially on uneven ground.

Real-World Applications in Dump Trucks

Typical Use Case Scenarios

Imagine a dump truck working on a steep job site or unloading sticky clay in wet conditions. A 4 stage cylinder might not reach the full angle needed for the material to slide out. The operator has to shake the truck bed or reverse multiple times. Not only is this inefficient—it’s risky.

With a 5 stage telescopic cylinder, that same load lifts higher, faster, and with more control. One smooth motion, and the load is dumped cleanly. No bouncing, no guessing.

Operator Feedback and Practical Benefits

Truck drivers and fleet managers often mention that 5 stage cylinders reduce wear on the truck frame over time. Because each stage takes a portion of the load during extension, the overall system handles stress better. Mechanics appreciate fewer mid-lift failures and a lower chance of cylinder leaks, assuming proper maintenance is followed.

Key Specs You Should Know

Stroke Length & Retraction Ratio

Typical 5 stage cylinders for dump trucks offer strokes from 4000mm to 8000mm. The retraction ratio (total extended length vs. retracted size) is one of the best in class. This is what allows high lift angles without requiring a huge space underneath the truck bed.

Bore Size and Stage Diameter

Stage diameters usually taper from large (main barrel) to small (final stage), often starting from 150mm and narrowing down to around 70mm. This tapering is what allows compact nesting and efficient force distribution during lifting.

Mounting Types and Compatibility

Look out for trunnion or pin-eye mounting options. These must match the structure of your dump body. Incompatibility can lead to uneven lifting or even catastrophic failure if the mounting is not properly aligned. Many manufacturers offer custom mount solutions for different dump body designs.

Common Challenges and Maintenance Tips

Even a top-tier hydraulic cylinder can fail early without basic maintenance. Here’s what real users suggest based on field experience:

- Always clean the rod between uses, especially after dumping wet soil or sand.

- Check for air in the system if the cylinder feels jerky or uneven during extension.

- Look for seal wear or oil leaks around each stage, particularly between the 3rd and 5th stages where the most pressure builds up.

- Replace hydraulic fluid on schedule. Dirty oil ruins internal surfaces quickly.

Routine maintenance may seem like a chore, but skipping it leads to longer downtimes and higher repair costs.

New vs. Rebuilt: What Makes Sense?

Buying a new 5 stage telescopic cylinder can cost anywhere from $2,500 to $6,000 depending on specs and brand. Rebuilt units are cheaper but come with risks. Unless you trust the supplier or have a reliable in-house mechanic, rebuilt cylinders might not last as long—especially in demanding applications like construction or mining.

If budget allows, go new. But if you’re running older trucks and only need a few more years out of the equipment, a quality rebuild could be a smart move. Just ensure the internal components, especially the seals and bushings, are fully replaced—not just cleaned up.

Final Thoughts: Is the 5 Stage Cylinder Right for Your Dump Truck?

For operators handling heavy or sticky materials, or for those working on job sites where a full dump angle is non-negotiable, the 5 stage telescopic hydraulic cylinder is a solid investment. It delivers higher lifting range, smoother operation, and better weight distribution across stages.

But like any hydraulic component, its performance is only as good as its installation and upkeep. Choose a reputable supplier, double-check your specs, and stay on top of maintenance. Do that, and your 5 stage cylinder could serve you reliably for years—one heavy load at a time.

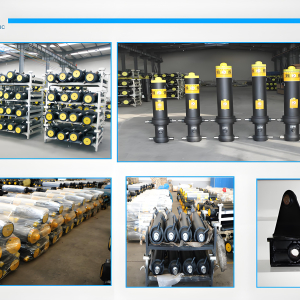

It is recommended to use various types of hydraulic cylinders, dump truck hydraulic cylinders, and telescopic hydraulic cylinders of our company