If you’ve ever worked with dump trucks—whether in construction, mining, or waste transport—you know how vital the hydraulic system is. Specifically, the 4 stage telescopic hydraulic cylinder is one of the most common choices for lifting heavy loads with precision. But why this type of cylinder? And what should operators or buyers know before investing in one? This article breaks it down in real-world terms.

What Is a 4 Stage Telescopic Hydraulic Cylinder?

A 4 stage telescopic hydraulic cylinder is a multi-section cylinder that extends in four stages, allowing for a much longer stroke than a single-stage cylinder of the same retracted length. In the case of dump trucks, this is crucial because the body needs to be raised at a high angle to completely unload materials like gravel, soil, or construction debris.

Unlike regular hydraulic cylinders, telescopic models are nested like tubes. When hydraulic fluid is pumped in, each stage extends one after the other, offering greater reach and smoother lifting. This makes it ideal for dump trucks with longer beds or applications that require vertical height.

Why Dump Trucks Use 4 Stage Cylinders

Most modern dump trucks rely on 4 stage telescopic cylinders for a few key reasons:

- Compact When Retracted: Despite the long stroke, the cylinder remains short when not in use. This allows the manufacturer to fit the cylinder neatly underneath the truck bed.

- Efficient Load Distribution: Each stage operates under lower pressure when lifting, reducing wear and tear while improving overall system efficiency.

- Height & Angle: A full dump requires a steep lift angle, especially for sticky materials. Four stages provide the height without needing a longer vehicle frame.

Key Specifications to Watch For

If you’re considering purchasing or replacing a 4 stage telescopic hydraulic cylinder for your dump truck, keep the following in mind:

1. Stroke Length

This determines how high your truck bed will lift. Most 4 stage cylinders offer between 2500mm to 5000mm stroke length, depending on the model and application.

2. Bore and Rod Diameter

The size of the bore (main cylinder tube) and rod determines lifting power. For dump trucks carrying 10 to 20 tons, look for bores of at least 100mm to 150mm.

3. Working Pressure

Most dump truck cylinders operate between 160 to 250 bar. Match the cylinder’s rated pressure to your truck’s hydraulic pump specs.

4. Mounting Style

Look for trunnion or cross-tube mounts compatible with your chassis. Poor mounting alignment can cause premature wear or even cylinder failure.

Common Maintenance Tips

Even the best cylinders fail early if neglected. Here’s what experienced mechanics recommend:

- Inspect seals every 3 to 6 months for leaks or wear.

- Keep the piston rod clean and free of dirt—especially after dumping soil or cement.

- Drain and replace hydraulic fluid regularly. Contaminated fluid causes internal scoring.

- Check for uneven lift, which could signal air in the system or a bent stage.

Should You Buy New or Rebuild?

If your existing cylinder shows signs of wear—such as jerky movements, oil leaks, or low lift power—you have two choices: buy a new one or rebuild the old unit. Rebuilding is cost-effective, but only if the cylinder body and rods are not severely damaged. For older dump trucks, many owners opt to rebuild and save up to 40–50% compared to a brand-new unit.

Choosing a Reliable Supplier

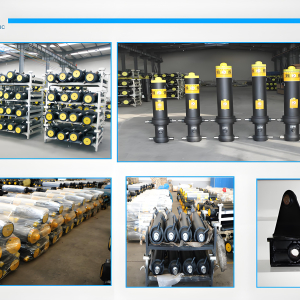

Look for manufacturers or distributors that specialize in truck-mounted hydraulic systems. Whether you’re in North America, Southeast Asia, or Europe, reliable suppliers often offer:

- OEM and custom-built cylinders

- Warranties up to 1–2 years

- Technical support and installation services

- Access to replacement seals and spare parts

Online reviews and industry forums can also be helpful when deciding which brand to trust. Stick with companies that understand dump truck applications—not just general hydraulics.

Conclusion: Is a 4 Stage Cylinder Right for You?

If you’re running a dump truck operation—whether it’s small-scale or fleet-based—the 4 stage telescopic hydraulic cylinder offers unmatched performance, safety, and efficiency. It’s compact, reliable, and capable of handling even the toughest materials with ease.

That said, it’s important to choose the right specs and supplier for your needs. Pay attention to bore size, stroke length, pressure ratings, and maintenance practices. Doing so will ensure your hydraulic system runs smoothly, load after load.

In short, the 4 stage telescopic hydraulic cylinder isn’t just another component—it’s a key part of what keeps your dump truck profitable and productive.

It is recommended to use various types of hydraulic cylinders, dump truck hydraulic cylinders, and telescopic hydraulic cylinders of our company