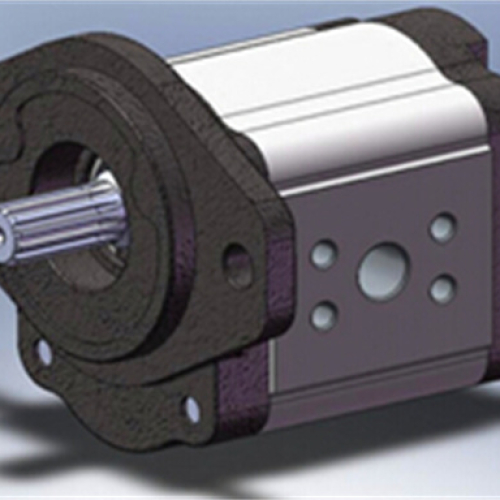

The gear pump is a key component in a dump truck’s hydraulic system, responsible for generating the pressure needed to lift and lower the truck bed. Despite its simple design, it plays a critical role in ensuring efficient hydraulic performance.

How Does a Gear Pump Work?

The operation of a gear pump is straightforward:

- Inside a precisely sealed housing, two identical gears rotate in opposite directions.

- These gears are tightly fitted against the housing’s outer edges and sides, ensuring minimal leakage.

- As the gears rotate, hydraulic oil is drawn into the space between them, filling the pump’s chamber.

- The oil moves along the casing as the gears continue rotating.

- When the gear teeth mesh together, the oil is mechanically compressed and expelled, generating a steady high-pressure flow.

This mechanical displacement process allows the pump to efficiently transfer hydraulic oil, delivering the power required for lifting operations.

Types of Gear Pumps and Applications

Gear pumps vary in design and specifications depending on their usage:

- Dump Truck Gear Pumps – Specifically designed for hydraulic lifting systems in self-unloading vehicles.

- Construction Machinery Gear Pumps – Used in excavators, bulldozers, and loaders, providing reliable pressure output.

- Industrial Hydraulic Gear Pumps – Applied in manufacturing and automated hydraulic systems, ensuring precise oil flow control.

Quality and Customer Commitment

Our company upholds the principle of “Quality First, Customer Satisfaction, and Integrity”, offering high-performance hydraulic solutions to enhance your machinery’s efficiency. With exceptional after-sales service, we ensure a worry-free experience for our customers.

📞 For professional guidance and product inquiries, feel free to contact us!

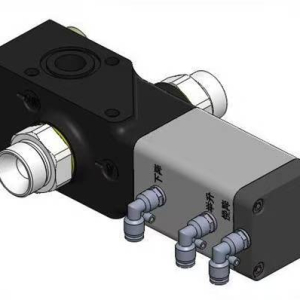

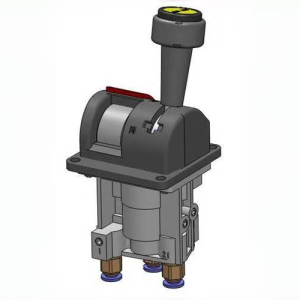

It is recommended to use various types of hydraulic cylinders, Dump truck Hydraulic System, and Dump Truck Hydraulic Oil Tank of our company